A common problem that is prevalent at the moment with the current competitive top dressing market is weight creep on the aircraft. Every kilogram of equipment is one kilogram less product being carried and delivered adding up to thousands of dollars of lost revenue per year.

Not only that but if the equipment brings the centre of gravity too far aft, this can much more dramatically affect the maximum amount of product that can be carried in the hopper for aircraft like the Cresco, Fletcher, and the 750XL with the hopper behind the cockpit.

This effect compounds. Generally the cost to operate the aircraft is calculated per hour, and consists of fixed costs and hourly operating and maintenance costs. If the aircraft can carry less, it has to fly more hours to get a job done. This causes the cost per tonne spread to go up. If this cost is above the rate that can be charged, the aircraft becomes uneconomical to operate. In a recent cost study carried out for one particular Cresco with aft centre of gravity limitation, replacing the hydraulic system with our electric actuator can increase the aircraft payload by as much as 880lb! This benefit is particularly evident when spreading lime. Because of the higher density, and the shape of the hopper, lime tends to cause aft centre of gravity limitations to come into effect on typical Cresco Aircraft.

Since the New Zealand farmer of today is being pressed to keep prices down they only have so much money to spend on fertilizer, and this budget is not staying ahead of inflation. This means top dressers are being forced to find ways of making their operations more cost effective to stay in the industry.

Aero Design is dedicated to developing solutions to reduce the weight of heavy role equipment. Our most recent products are the Carbon Fibre “Gatebox” (Hopper Outlet Valve) and our Electric Carbon Fibre Gatebox Actuator. Both these units combined weigh less than 24 kg where typical steel gatebox and hydraulic actuation systems would weigh well over 100 kg.

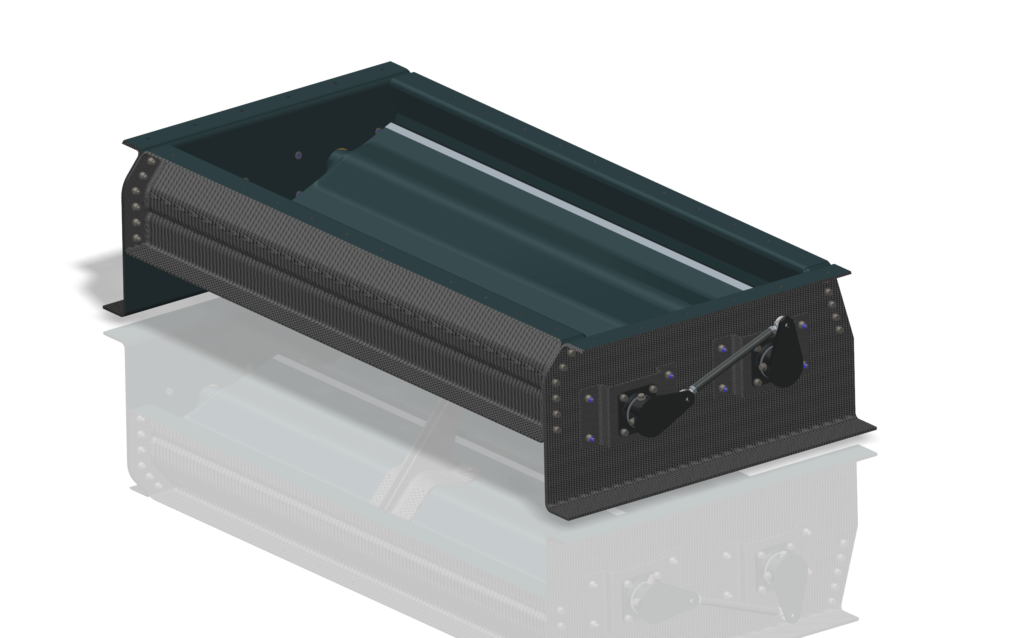

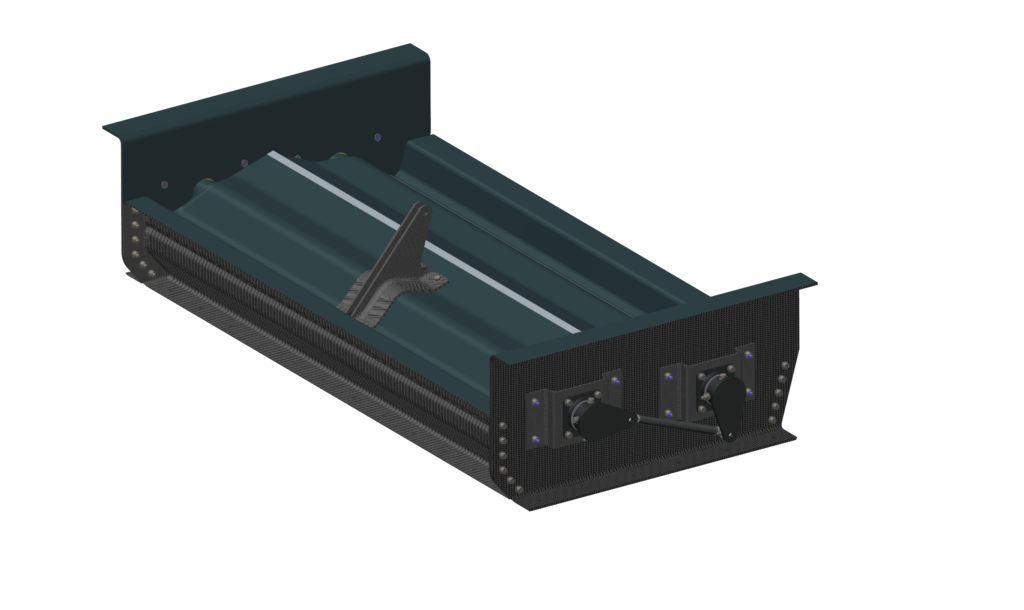

Carbon Fibre Gatebox

Our carbon fibre gatebox features our proprietary wear resistant coating which protects the inner surfaces of the gatebox better than any other ceramic coating or similar coating products.

We have improved our carbon fibre gatebox design dramatically in order to improve production time and dramatically reduce the cost to the customer. The new carbon fibre gatebox design will be priced comparably with an equivalent aluminium gatebox but with a much lower weight.

Only the two vane wide outlet gatebox is shown here, but we also have configurations defined for three vane narrow hopper outlet, and three vane wide outlet (750XL). This means that we can cover a wide variety of top dressing aircraft including the Cresco, Fletcher, 750XL, Air Tractor, Ag Cat, Cessna Ag Truck, Dromader, and Thrush.

The gatebox is constructed by Aero Composites using high quality components and Aero Design and Aero Composites is dedicated to providing support to the customer for maintenance.

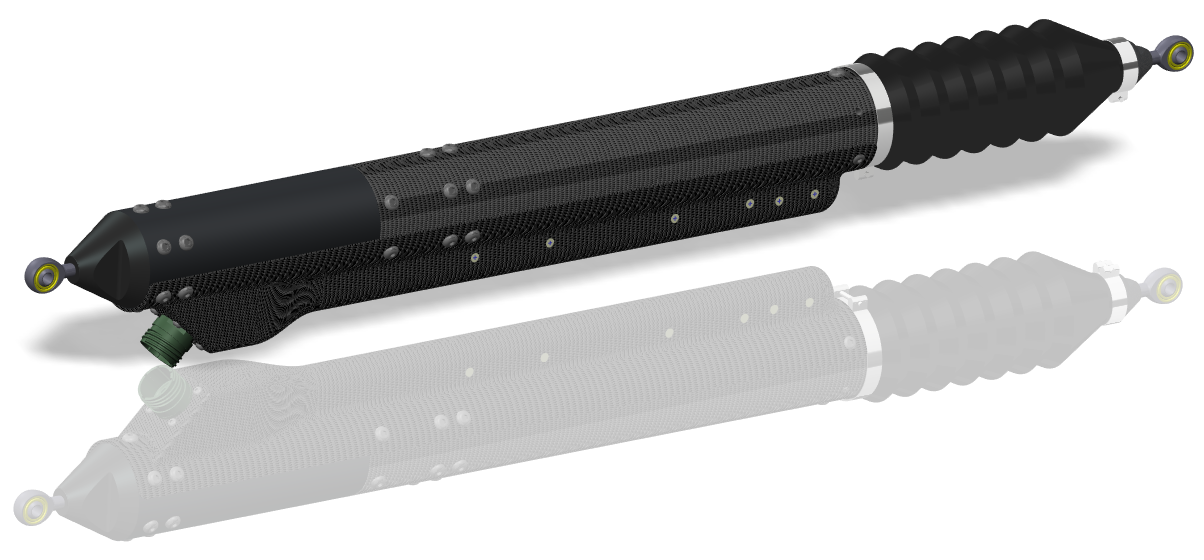

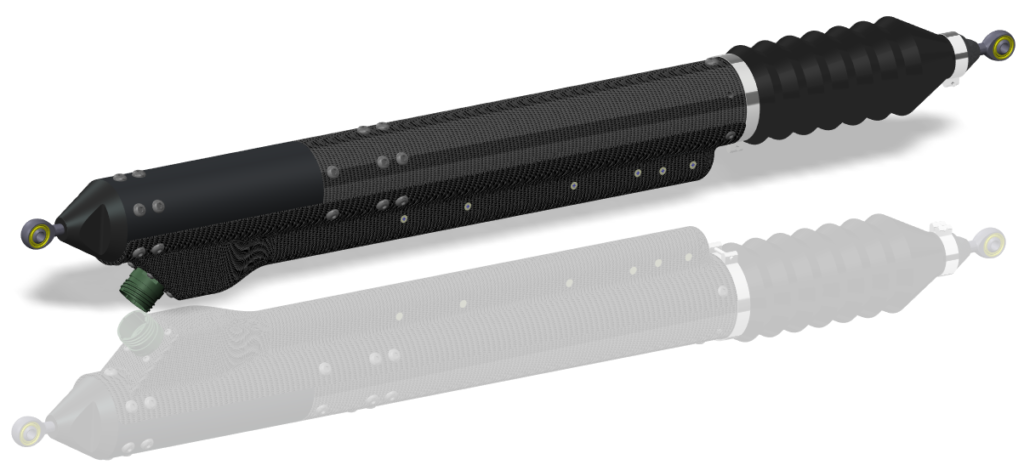

Electric Carbon Fibre Gatebox Actuator

Our new Electric Carbon Fibre Gatebox Actuator replaces all of the heavy hydraulic systems required to drive a hydraulic piston. Due to the high pressure of hydraulics it is all typically steel components which are very heavy. Hydraulic systems also require additional redundancy to provide adequate safety so that the pilot can always dump the hopper contents in an emergency situation. When a hydraulic system dumps it usually dumps the entire load even if a complete dump is not required.

Our actuator replaces the physical link rod between the pilot’s mechanical hopper control lever and the gatebox meaning that if an emergency dump is required, the pilot can do this normally without the need to rely on the actuator to perform the dump. This means that if only a partial dump is required the pilot can do this exactly the same as might be done with a manual system. While the manual hopper lever is down the electric actuator opens and closes the gatebox for normal spreading operations controlled by the existing hopper outlet control system.

Aero Design developed an open controller that can easily integrate with whatever control system you are currently using, whether it be a Satloc, TracMap, or another proprietary control system.

Our actuator is capable of moving 200 to 300 mm per second with a maximum force of over 3 kN and a working load of 1.2kN. It also features an absolute linear position encoder with a precision of 5 micro meters to give your control system the fine control that it needs to perform optimally.

The actuator has been designed with reliability and ease of maintenance in mind. Rather than sending the actuator away to the manufacturer to be overhauled, all the wearable parts are replaceable by the maintenance organisation in accordance with the actuators maintenance manual. All the components can be purchased separately from Aero Composites if replacements are required and Aero Composites is dedicated to providing this support.

The actuator can be ordered in the length and stroke you require. Click on this link for more details and the order form.

Other Weight Savings

There are many areas where we can help save weight on the top dressing aircraft:

- Replacing heavy and cracking fibreglass fairings with stiffer and lighter carbon fibre fairings. We have already got designs for Cresco carbon fibre aileron tip fairings and fences, carbon fibre hopper outlet fairings, and carbon fibre engine cowling.

- Replacing heavy landing gear mud-guards with stronger lighter carbon fibre mud guards. We currently have a carbon fibre mud guard design for the Cresco main landing gear. This mud-flap would be easily adaptable to Fletcher and 750XL.

- Certified Lithium-Ion battery installation replacing the heavy lead acid batteries in the tail of the aircraft.

- Replacing plywood floor boards with carbon fibre sandwich panel floor boards. We currently have a design for Cresco carbon fibre floor boards available.

Contact us if you have any further enquires about how we can help make your top dressing operation more efficient.

Aero Design

Aero Design